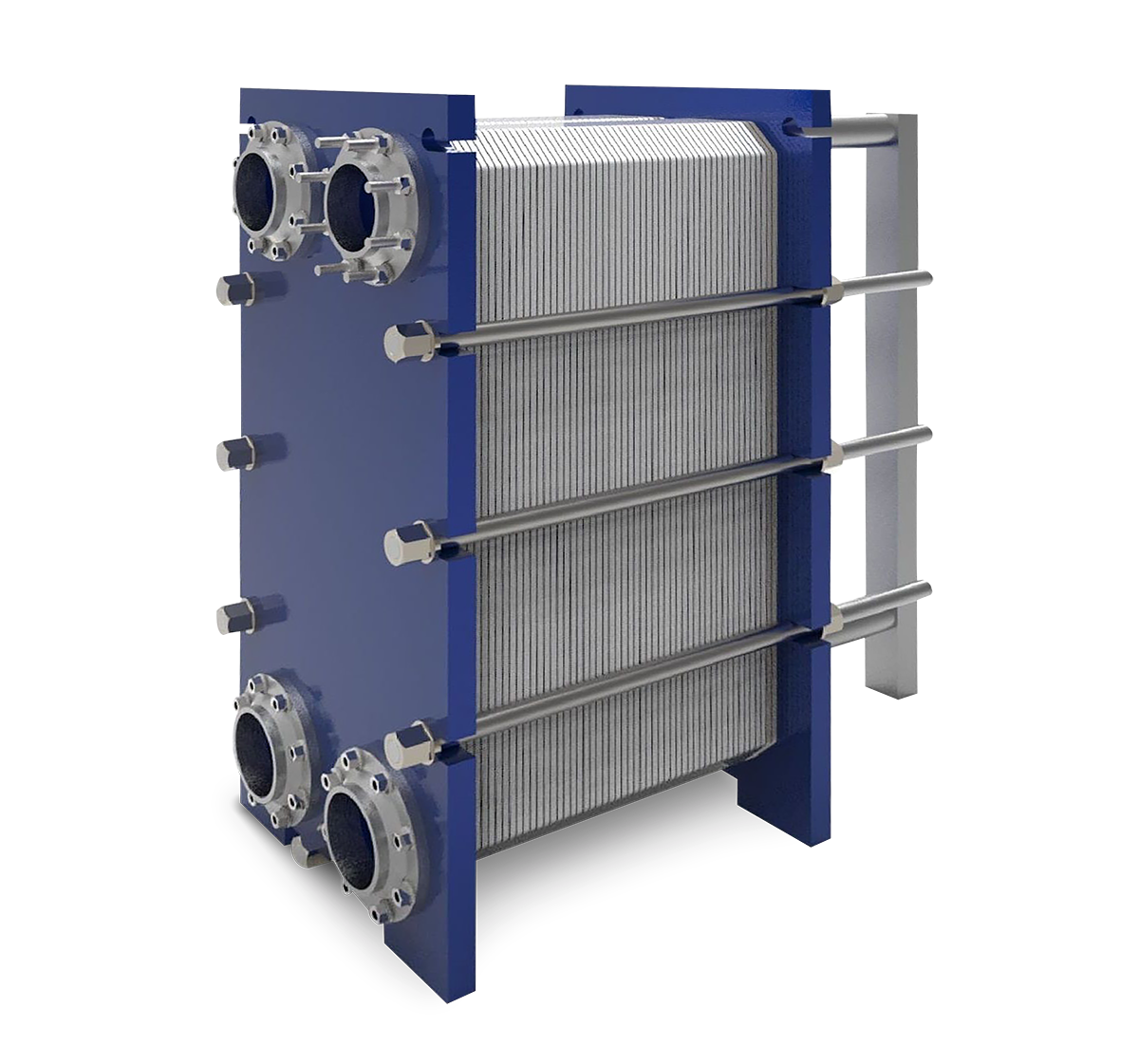

Plate and Frame Heat Exchanger

Available with Uptime®

The Smarter Way to Manage Heat Recovery

No two operations are exactly alike. Some plants run three shifts, others one. Some are highly automated, others rely on the experience of a skilled crew. But whether you are heating water for sanitation, recovering energy from a process stream, or maintaining consistent temperatures in a production cycle, one thing holds true across industries: you need dependable heat transfer and you cannot afford a system that slows you down.

That is where Plate and Frame heat exchangers prove their value. With high thermal efficiency, a compact footprint, and straightforward maintenance, these systems are trusted in a wide range of manufacturing environments because they do what they are supposed to do. They perform day in and day out, require less hands-on attention, and help keep your production schedule on track.

Product Features

-

High Heat Transfer Efficiency

-

Compact Footprint

-

Modular and Scalable

-

Easy Maintenance and Cleaning

-

Customizable Plate Materials

-

Gasket or Welded Plate Options

-

Low Fouling Design

-

Minimal Pressure Drop

-

Sanitary Design Available

-

Energy Recovery Capability

-

Flexible Mounting Options

-

Multiple Pass Configurations

-

Reliable Sealing Technology

-

Proven in Demanding Environments

More Product Features

The Plate and Frame heat exchanger maintains consistent thermal performance, even with fluctuating flow rates or start-stop conditions. Precision plate spacing and optimized patterns promote even fluid distribution, which reduces bypass, cold spots, and fouling. The rigid frame resists deflection under clamping pressure, helping gaskets stay sealed and extending service life.

For tighter process control, units can be fitted with ports for temperature, pressure, or flow sensors to support real-time monitoring and system integration. Optional insulation minimizes heat loss and improves energy recovery. Multi-pass configurations and custom plate designs help optimize pressure drop and thermal output to match specific application requirements.